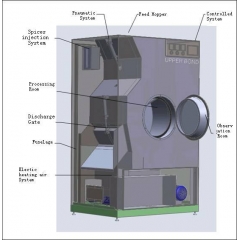

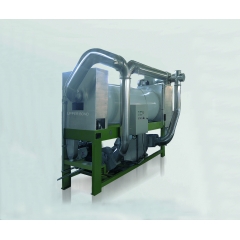

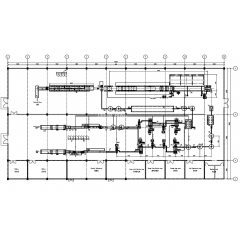

With more than 16 years tobacco industry technology research and design experience, we developed “small capacity, low cost but high quality” tobacco processing technology and machines for match the pilot primary processing line. Capacity is from 200kg to 1000kg.

The whole producing procedure can be divided into following sections: lamina processing section, cut-lamina processing section, stem processing section, cut-tobacco blending section, Burley tobacco processing section.

This section includes the procedure of bale opening, vacuum humidifying, loosening, conditioning, casing and storing, etc.

This section includes the procedure of lamina cutting, constant flow rate control, cut-lamina expansion and drying, etc.

This section includes increasing temperature and moisture, storing, cutting, expansion drying, etc.

This section is to blend cut-lamina, cut-stem, expanded cut-tobacco and reconstitute tobacco in proportion according to batch formula by pass through auto feeders.

Section 5. Burley tobacco processing section

Related Tags : Tobacco Primary Processing Machine Tobacco Processing Equipment Tobacco Primary Line

Previous:Tobacco Threshing Production Line

Next:BYJ Tobacco Sewing Machine

-

-

-

-

-

-

-

MK8-D Cigarette Making Machine with MAX-III Filter Assembler – 2500 Cig/Minute

-

Automatic Cartoner Machine for Small Box Packaging with PLC & Engine

-

Embossing Roller Customer Pattern Design For Cigarette Packing Machine

-

Ordinary Circular Blade Cigarette Machine Parts 100mm Thin For Filter Rod

-

Glue Application Wheel for HLP2 Cigarette Box Packing Machine

-

-

Dual-Heating HNB Device for TEREA / SENTIA Magnetic Tobacco Sticks

-

High Tech Automactic Case Packer for Cigarette Carton Packaging

-

-

Negative Air Pressure Vacuum Blower for Cigarette Making Machine