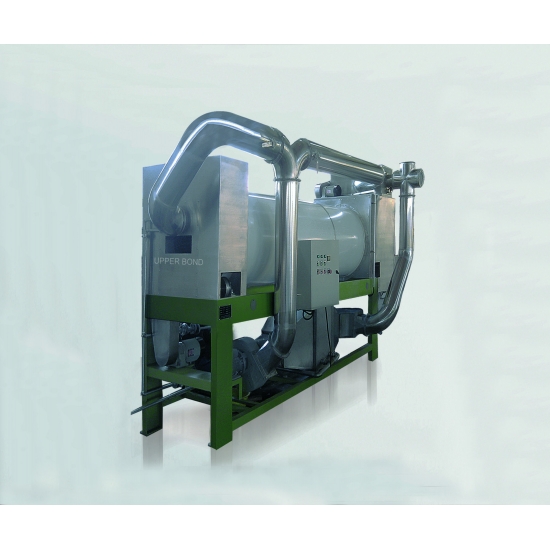

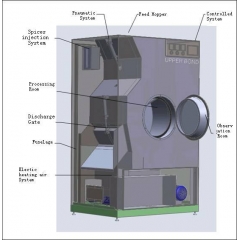

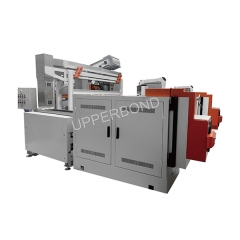

Cut Tobacco Drier

Procution Process: Tobacco baking, Cut tobacco drying, Tobacco cutting

Main Functions & Feature

⑴ This machine is designed for cut material drying to improve crimp ratio, filling value and quality.

⑵ The roller features a sloping and revolving cylinder.

⑶ Adjustable temperature range with a maximum of 120℃.

⑷ Simple structure, easy operation, low malfunction and less maintenance costs.

⑸ This dryer is equipped with both radiant and air circulation heating drying systems (downstream hot air mode).

Main Technical Parameter

No. |

Item |

Unit |

Parameter |

Remrks |

1 |

Rated capacity |

kg/h |

100 - 300 |

|

2 |

Supplied material moisture content |

% |

20% - 30% |

|

3 |

Supplied material temperature |

℃ |

30 |

|

4 |

Discharging material temperture |

℃ |

70 - 95 |

adjustable |

5 |

Discharging material moisture content |

% |

12 - 14 |

adjustable |

6 |

Roller speed |

rpm |

10 - 20 |

adjustable |

7 |

Steam pressure |

MPa |

0.8 |

|

8 |

Compressed air |

MPa |

0.6 |

|

9 |

Installed power |

kw |

4.5 |

|

Supply Instruction

⑴ Sold in complete machine

⑵ Main material: 3mm 304 stainless steel cylinder wall, rest is carbon steel.

⑶ Wires and pipes except for those for the main engine are not within the supply scope.

⑷ This machine has a moistureremoving air pipe joint. The air pipe flange and dust remover device should

be equipped by the purchaser.

⑸ The electric motor is featured with simple electronic control, which enables manual valve control of

temperature, moisture and blast capacity.

Related Tags : Tobacco Baking Tobacco Drier Dry Tobacco

Previous:IMS-W8B Infrared Moisture Measurement

Next:Tobacco Machine For Chewing Tobacco Process Line

-

-

-

-

-

-

Automatic BOPP PVC Film Wrapping Machine with Touchscreen & Servo Control

-

Ordinary Circular Blade Cigarette Machine Parts 100mm Thin For Filter Rod

-

-

-

P-180 Cigarette Packing Machine Five Phase Tobacco Packing Machine 380V 60HZ

-

Double Blade Knife Disc Assembly for MK8 Cigarette Maker Machine Replacement

-

Protos 70 Grinding Wheel for Blade Sharpening Wheel for Cigarette Cutter Knives

-

-

-

-