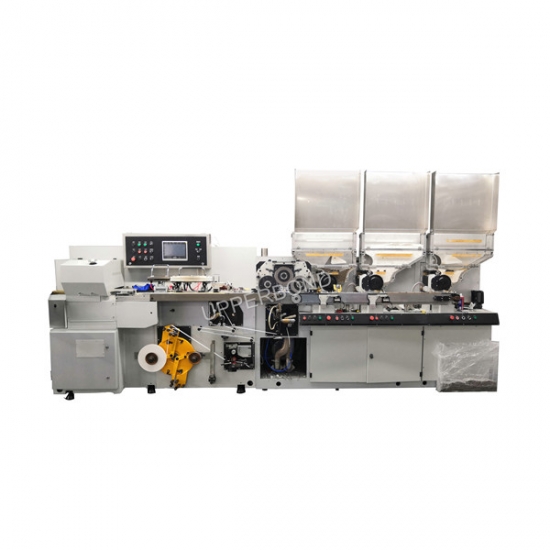

| Dual Filter | Triple Filter | |

| Model | FC200 | FC100 |

| Capacity | 200 m/min | 100 m/ min |

| Filter diameter | 5.4-7.9 mm | 5.4-7.7 mm |

| Filter length | 90-150 mm | 90-150 mm |

| PLC | Siemens | Siemens |

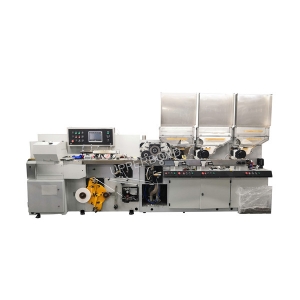

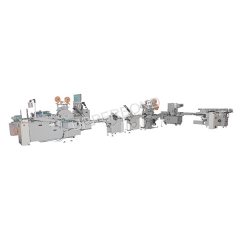

The Modular Linear Composite Machine utilizes linear composite technology to divide base rods of various specifications into short rods according to requirements. These short rods are transported via a chain conveyor and turned sequentially by a rotary disk, then placed onto the suction belt in an orderly manner with a certain gap between each segment. Different types of short rods are alternated in the required sequence.

Related Tags : Filter Combiner Modular Linear Ternary Composite Machine HNB Machine

Next:Laboratory Combiner Equipment For Testing HNB Stick Sample

-

P-180 Cigarette Packing Machine Five Phase Tobacco Packing Machine 380V 60HZ

-

CLT CRIMPER and MAKER Tobacco Form Recon Rod Machine For Heat Not Burn Stick

-

-

-

-

-

-

-

Glue Nozzle Kit Precision Hma Dispensing Tip for Automatic Cigarette Lines

-

-

-

-

-

-

White Belt Tobacco Nylon Suction Tape For MK8 MK9 Cigarette Machine

-

Nylon Conveying Suction Tape JIULONG for Cigatette Making Machine