- UBD-TP

- China

- T/T, 50% deposit in advance, 50% balance befo

- 15-30 days

Instruction

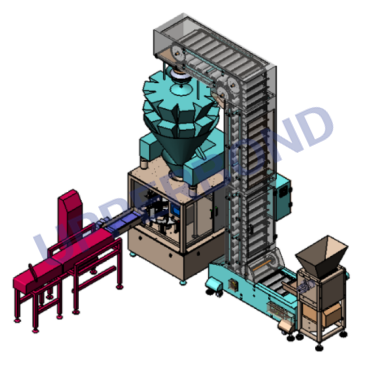

This line is used for RYO Roll-Your-Own Tobacco, which fills tobacco cut rag into small pouch. It is customized by sample from the customer. Its packaging process is from scattering tobacco, elevating, quantitative weighing, forming to sending out automatically, artificial bag packaging, then outer packaging by packaging machine.

This line adopt the advanced technology from Oversea, we design it in a high quality, high-powered fully auto feeding, measuring, filling, sealing, printing date and product carry-out packaging machine after improving. This machine adopt PLC control, advanced touch screen, photocell auto orientation tracking, it can make the machine operation more simply, perfect, it is the best equipment for food line for high production efficiency, low labor intensity.

Packaging Process

Scattered Feeder — Elevator — Quantitative Weighing — Forming —Sending Out — Bagging by Manual — Outer Packaging

Line unit

Threshing Feeder + Z-Lifter + Combined Weigher + Auto-Forming Compressing Pouch Packer + Weight Control Device

Parameter

| Material | RYO tobacco |

| Tobacco weight | 20 - 50 g |

| Capacity | 20 - 30 pouch/min |

| Power | 220 V, 50/60 HZ |

| Air Source | 6—8 KG/cm2 |

| Dimension | 4000*3000*3000 mm |

| Weight | 1500 KG |

| Packing | Wooden Case |

Features

1. This packing line is customized for tobacco pouch filling. As the tobacco is very slim, and compressed in the carton, so it is easily intertwined together, will not flow well on the machine, so we put threshing unit on the feeder system, to make tobacco fluffy.

2. This line is a high-quality, high-performance automatic packaging machine produced by introducing advanced foreign technology and improving it. It has a series of automatic functions including automatic feeding, weighing, filling, sealing and finished product output.

3. PLC process control, advanced touch HMI, and photoelectric automatic positioning tracking system, altogetherly make operation of the whole machine simpler and more completed. It helps food packaging industry improve production efficiency, reduce labor intensity, and improve packaging grade.

4. As tobacco is expanded, so it is difficult to loading much in the pouch without compressed. The Auto-Forming Compressed device is customzied for tobacco packing, which will compress the tobacco into shape, then packed into the pouch easily.

5. Equipped with weight control device at the output end, to reject finished pouch which is out of tolerance weight.

6. The main body of equipment is mainly made of high-quality 304 stainless steel and aluminum alloy materials. The machine is equipped with safety protection doors.

Pictures

Related Tags : RYO Roll Your Own Tobacco Pouch Filling Line

Next:20 - 30 Bags / Min Cut Tobacco Packaging Machine 50G / Bag

-

-

-

YL43 Dual/Triple Charcoal Filter Rod Maker (Special combination)

-

-

Protos 70 Grinding Wheel for Blade Sharpening Wheel for Cigarette Cutter Knives

-

-

22*2800mm Garniture Tape For Transfers Cigarette Paper And Tobacco

-

Embossing Roller Customer Pattern Design For Cigarette Packing Machine

-

Ordinary Circular Blade Cigarette Machine Parts 100mm Thin For Filter Rod

-

-

Sharpen Blade MK8 MK9 Grinding Wheel Grinding Stone White Round Grinding Wheel 7*10*6mm

-

-

-

King Size Slitting Blade Knife for Cigarette Machine Spare Parts

-

-