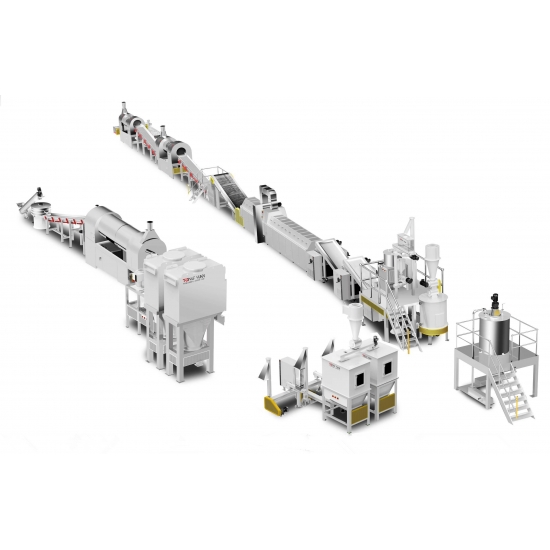

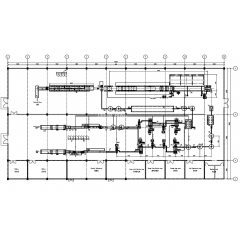

Rolling-base Tobacco Sheet Production Line

Application: Cigar or Cigarette Production

INTRODUCE

Rolling-base Tobacco Sheet is the original recipe for reconstitute tobacco sheet manufacturing dating back to the middle 20th century when tobacco reclaiming and recycling. The tobacco sheet can be applied in cigarette reproduction or cigar making area to boost the utilization of cut-tobacco and it's dust etc... Nowadays Rolling-base is gradually fade out of the prevailing market being replacing be paper-base method.

The LB14 Rolling Process Reconstituted(Recon) Tobacco Sheet Production Line (hereafter called as LB14) is one complete group of equipment which makes full use of tobacco waste such as tobacco stems, powder and dust etc. produced in cigarette manufacturing process. It adopts special technical recipe and flow to finally remake the waste into tobacco Sheet filament.

This production line has the advantages of small investment, environment protection without pollution during manufacturing, reducing cigarette production cost greatly and producing great economic profit.

The production capability of LB14 has four specifications of 200kg/h、400kg/h、600kg/h、800kg/h.

MAIN FEATURES:

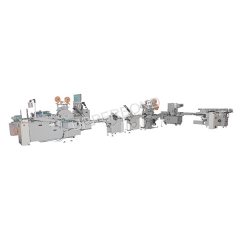

1. Pre-treatment section adopts the working procedures of vibratory sieving, iron removing and pneumatic classification, to effectively eliminate the impurity of the raw material so as to raise the purity of the materials.

2. The tobacco stem and powder adopts time-sharing drying on line and automatic classification storage. The stem and powder are proportioned automatically under the accurate control of screw electric scale with its error less than 2%. What’s more, it is convenient to adjust the proportion between the tobacco stem and powder. The drying of tobacco stem and power adopts the drying cylinder with dehydration capacity is more than 6%. After drying, the material has moisture of not more than 10%, which is easy to be grinded.

3. The material pneumatic conveying system and grinded material pneumatic conveying system both adopt negative pressure operation, two-stage dust discharging, which improves the environment of workshop.

4. Stem bin and powder bin both have been installed with material positioning sensor, which achieves an automatic start/stop of equipment through the signal interlocking.

5. The measuring of liquid and solid material all adopt decrement electronic scales .It can control the accuracy of materials output through frequency conversion control. It can ensure the moisture accuracy ±2% after blending.

6. LB14 adopts advanced technology in stem defibration. The tensile strength of recon will raise over 100% after adding stem fiber. It raises greatly the valid utilization rate of the sheet which is ≥ 95%.

7. The adoption of the second time crimping technology can raise the filling value of cut-recon. After the drying & crimping cylinder, there is a cooling device which cools down temperature of recon and helps shape-forming of the product quickly.

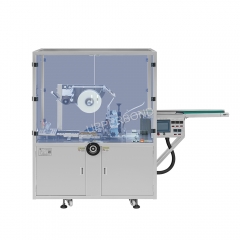

8. It sets up moisture automatic control system. It can assure the moisture deviation ≤±1.5% after cutting. The moisture deviation of finished product is not more than ±1%.

9. The control system is set up according to different control level; it is practical and advanced, easy for operation.

a. The control system has manual and auto operating modes. Manual operation is used in maintenance and on-site emergency treatment. Auto mode is used for normal production.

b. The system adopts PLC controller with high reliability and good brand low-pressure electrical components, and make the whole line operate automatically by start-stop in sequence control and by conditional interlocking. It gives real-time warning and indication for over current, lack of phase, short circuit etc. It is easy to maintain and repair. The system has high reliability.

c. The accuracy of measuring and blending of powder and liquid material can reach 99%. The blending ratio can be flexibly adjusted. The technology and production capacity have good adaptability.

d. As to those sections with high requirements for flow, speed, moisture and temperature, it adopts intelligent instruments, such as frequency control, temperature control apparatus, dynamic measuring electronic scales and moisture apparatus etc, it can be monitored and supervised locally, and it is also supervised by the upper-digit computer in concentration.

e. The upper-digit computer can achieve the concentrated supervision in order to facilitate the management on-line. It can generate production report forms showing material consumption and product statistics for data storage.

Related Tags : Reconstituted Tobacco In Cigarette Production Tobacco Reclaiming For Cigarette Making Tobacco Sheet For Cigar