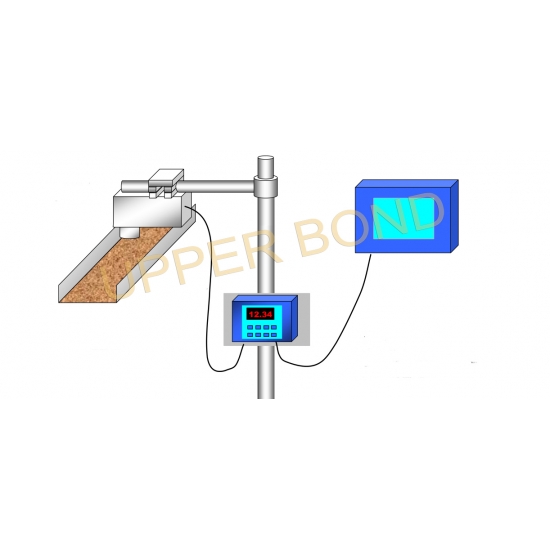

IMS-W8B Infrared Moisture Measurement

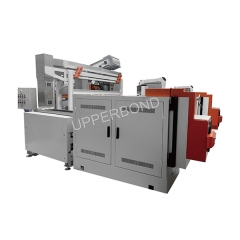

Production Process: Cut Tobacco drying, tobacco baking, tobacco moisture content measure, tobacco cutting

FEATURE

1. Wide applied range

It could be used in the moisture content online measure of all kinds of material, for example, tobacco, MDF(Medium Density Fiberboard), chipboard, glass, balling, firing, film, plastic, food, paper-making, fodder, chemical product, grease, china, mineral and other industry.

2. Non-contact, quick response

The common method to measure the material’s moisture content is Oven-drying. But the disadvantage is that it would take more operation time, and the information is lagged severely. Therefore, such method could not be applied in the production line, but only in the laboratory. However, IMS-W8B Infrared Moisture Measurement could continuously measure the material and contact-less. It realizes the online real-time measure. The response time is 8ms only, which could control the product’s moisture content in time.

3. Multichannel setting, meet the need of all kinds of materials with one machine

There are 16 channels in IMS-W8B, with the number from1 to 16. Every channel number represent a channel parameter. Once the channel number is altered, different channel parameter is chosen to meet the need of all kinds of materials with one machine.

4. Stable and high precision

There are 8 light beam in IMS-W8B Infrared Moisture Measurement, which would have much higher stability than those have 4 and 6 light beam. The average measure precision would reach to 0.1% to 0.5% (according to the material). It really meet the requirement of the manufacturing technique.

5. Easily installation and operation

It only takes several days to install and debug and it could be operated during installation. Prescaler is used in IMS-W8B Infrared Moisture Measurement. After fixing the intercept, it could accomplished the work. The machine could work numbers with singlechip. The simple touch operation is quite suitable for the operators.

Related Tags : Moisture Content Control Moisture Content Measure Infrared Moisture Detector

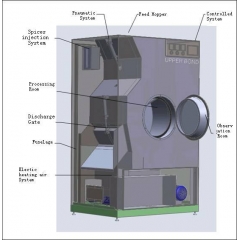

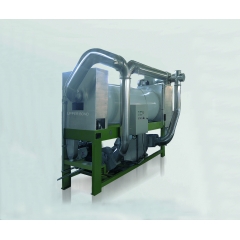

Next:Cut Tobacco Drier